Thanks for visiting dragon machinery at thermal paper slitting machine!

I am sure this coreless thermal paper rolls is one trend. in order to following in this trend, our factory research the CORELESS TYPE THERMAL PAPER SLITTING MACHINE.

CORELESS TYPE THERMAL PAPER SLITTING MACHINE

many thermal paper rolls manufacturer produce the thermal paper rolls,cash register rolls with paper cores or plastic cores before. in fact, the paper core or plastic cores is just let the thermal paper rolls manufacturers more conveniently. it is really not necessary for the ending customer to use this plastic cores or papper cores. we can say that the thermal paper rolls with cores is one kind wasting. furthermore,when producing the thermal paper rolls with paper cores or plastic cores, it need insert some raw materials into the cores. then it result in the waste of raw materials.

now in order to save more cost,certianly it is also in order to satisfy with more and more ending customer, many thermal paper rolls manufacturer start to produce the cash register rolls without cores.I am sure this coreless thermal paper rolls is one trend. in order to following in this trend, our factory research the CORELESS TYPE THERMAL PAPER SLITTING MACHINE.

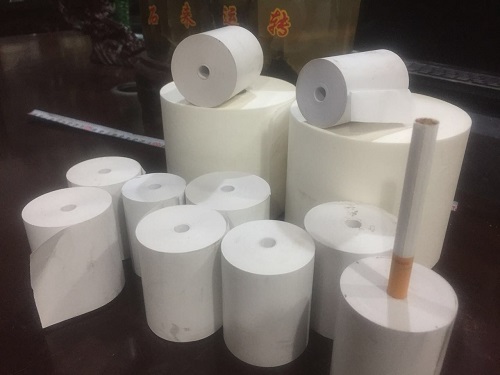

the below is the photos for our CORELESS TYPE THERMAL PAPER SLITTING MACHINE and the products which produced by this machine. if you want to know more aboutthis type CORELESS TYPE THERMAL PAPER SLITTING MACHINE, pls watch the below link

https://www.youtube.com/watch?v=PQvLNh3z_9U

Material: 45-200g paper, thermal paper, POS cash register, ATM roll etc

The maximum width of the jumbo reel:700mm

The width of the small slitted reel by the machine: 30-900mm

Working speed: 150m/min

Slitting speed: 5-150m/min

The maximum unwinding diameter: 1200mm

The unwinding shaft: locked 3" air expanding shaft

Unwinding tension force 10N

The maximum rewinding diameter: 220mm

coreless type and without rewinding shaft

The main motor: 2.2 KW frequence inverter control

The fan motor: 0.55 kw single phase motor

The transimmission way: chain, gear and synchronization strap.

Slit: round cutter(the size is according to the machine)

Shaft: 80 hard aluminium alloy

Length of guide rod: 720mm

Machine material: steel board and cast iron

Working voltage: three phase four line, 380V, 50HZ

Total power: 4.5 kw

Weight: about 1600 kgs

Overall dimension( L×W×H ) 2.2M×2.1M×1.3M

B Configuration and function

Control panel: PLC it has meter accounting,stop automatically if paper break, inspecting the left material and speed adjusting automatically.

Rewinding tension force: adopt the impulse type sensor for control automatically

Main motor: adopt the three phase, 3 kw frequence inverter control

Lift/drop for unwinding stand: adopt the mechanic chain control way.

Traction: rubber rod

Unwinding arrester: 10 NM

Low-pressure electric part: made in China

Look back [Automatic Thermal Paper Slitting Machine]